The Arena / FlexSim – Simulation of Manufacturing Systems Course is designed to equip learners with practical knowledge of discrete-event simulation (DES) tools widely used in manufacturing and industrial systems. Arena and FlexSim are powerful software platforms that allow engineers and managers to model, analyze, and optimize complex processes, enabling data-driven decision-making, cost reduction, and productivity improvement. This course bridges the gap between theory and real-world applications in production, logistics, and supply chain systems.

Module 1: Introduction to Simulation & Modeling Basics of system modeling Types of simulation (discrete, continuous, agent-based) Applications of simulation in manufacturing and logistics Simulation project life cycle.

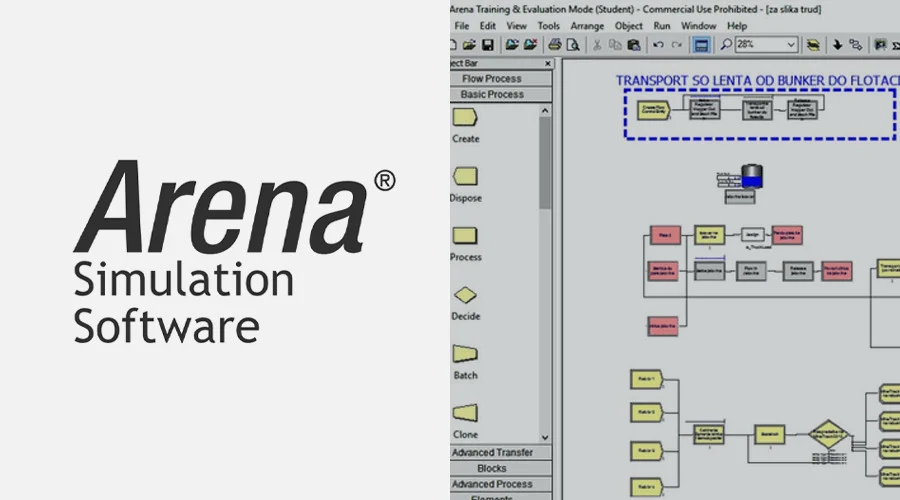

Module 2: Getting Started with Arena & FlexSim Installation, interface, and navigation Building first simulation models Entities, attributes, variables, and parameters Importing and exporting data.

Module 3: Discrete-Event Simulation Concepts Event scheduling and process interaction approaches Queues, resources, servers, and routing logic Flowchart modules and logic building Debugging simple simulation models.

Module 4: Modeling Basic Manufacturing Systems Single-machine and multi-machine systems Job shop and flow shop modeling Material handling basics Resource allocation in production.

Module 5: Advanced Manufacturing Simulation Assembly lines and production cells Batch processing and setup times Preventive maintenance modeling Downtime and repair simulation.

Module 6: Logistics & Supply Chain Simulation Warehousing and material handling systems Conveyors, transporters, and AGVs (Automated Guided Vehicles) Inventory and distribution modeling Supply chain demand–capacity analysis.

Module 7: Data Collection & Input Analysis Collecting and preparing data for simulation Fitting statistical distributions (Normal, Poisson, Exponential, etc.) Input data validation techniques Using Arena Input Analyzer & Flextime input data tools.

Module 8: Output Analysis & Verification Key performance indicators (KPIs) in manufacturing systems Model verification and validation methods Confidence intervals and statistical accuracy Using reports, dashboards, and charts.

Module 9: Optimization & Experimentation Scenario testing and sensitivity analysis Bottleneck analysis and system improvement Optimization using opt Quest (Arena) and Experimenter (Flextime) “What-if” analysis for decision-making.

Module 10: Industry Case Studies & Projects Assembly line balancing & optimization Warehouse operation efficiency improvement Production scheduling & resource allocation models End-to-end supply chain simulation project.

Mobile: 9100348679

Email: coursedivine@gmail.com

You cannot copy content of this page