Automated industry 4.0 Course in Visakhapatnam | You can find a wide range of courses on automated Industry 4.0, from free online primers to in-depth university certifications. These programs cover the core concepts of intelligent automation, connecting machines, and leveraging data for smarter factories.

Key topics covered in Industry 4.0 automation courses

- Industrial Internet of Things (IIoT): Automated industry 4.0 Course in Visakhapatnam | Connecting devices and machines with sensors to collect real-time data for better monitoring and control.

- Robotics and Automation: Programming and integrating robotics systems for automation, including collaborative robots (cobots).

- Cyber-Physical Systems (CPS): Integrating the physical and digital worlds to create intelligent, interconnected production environments.

- Big Data and Analytics: Automated industry 4.0 Course in Visakhapatnam | Analyzing the large amounts of data generated by IIoT devices to gain insights for decision-making and process optimization.

- Cloud Computing: Providing the infrastructure and connectivity for most Industry 4.0 technologies and storing the large amounts of data they produce.

- Artificial Intelligence (AI) and Machine Learning (ML): Used to enhance automation systems, enabling predictive maintenance and more adaptive, intelligent machines.

- Cybersecurity: Implementing robust security measures to protect the connected industrial systems from malicious attacks.

- Digital Twin and Simulation: Creating virtual replicas of physical systems to simulate production processes and predict performance.

Automated industry 4.0 Course in Visakhapatnam | Of course. Here is a comprehensive and structured outline for an Automated Industry 4.0 Course, designed to provide a holistic understanding of the technologies, strategies, and implementation frameworks of the Fourth Industrial Revolution.

Course Title: Mastering Industry 4.0: Automation, Data, and Connected Systems

Target Audience: Automated industry 4.0 Course in Visakhapatnam | Manufacturing engineers, plant managers, operations directors, IT professionals in manufacturing, automation engineers, business leaders, and students aiming to work in modern industrial environments.

Prerequisites:

- Automated industry 4.0 Course in Visakhapatnam | A basic understanding of manufacturing processes.

- Familiarity with fundamental IT concepts (networking, data) is helpful but not mandatory.

- An interest in technology, automation, and business strategy.

Course Goal: Automated industry 4.0 Course in Visakhapatnam | To equip professionals with the knowledge to understand, strategize, and implement the core technologies of Industry 4.0 to create smarter, more efficient, and connected manufacturing operations.

Detailed Course Modules

Module 1: The Fourth Industrial Revolution – Foundation & Vision

- 1.1 Evolution of Industry: From mechanization (1.0) and electrification (2.0) to automation (3.0) and cyber-physical systems (4.0).

- 1.2 Core Principles of Industry 4.0: Automated industry 4.0 Course in Visakhapatnam | Interoperability, Information Transparency, Technical Assistance, and Decentralized Decisions.

- 1.3 The Smart Factory Vision: A fully flexible, self-optimizing, and adaptive manufacturing system.

- 1.4 Drivers & Benefits: The business case for I4.0: mass customization, reduced time-to-market, increased efficiency, new business models.

- 1.5 Challenges: Workforce skills gap, data security, high initial investment, integration with legacy systems.

Module 2: The Core Pillars of Industry 4.0 (The “How”)

- 2.1 IoT (Internet of Things) & IIoT (Industrial IoT): Sensors, actuators, and connected devices on the shop floor. Protocols like OPC UA and MQTT.

- 2.2 Big Data & Advanced Analytics: Collecting, storing, and processing vast amounts of machine and operational data.

- 2.3 AI & Machine Learning in Manufacturing: Predictive maintenance, quality control (computer vision), demand forecasting, and process optimization.

- 2.4 Cloud & Edge Computing: Automated industry 4.0 Course in Visakhapatnam | The role of the cloud for massive data storage and powerful analytics vs. edge computing for low-latency, real-time control.

- 2.5 Additive Manufacturing (3D Printing): For rapid prototyping, custom tools, jigs, fixtures, and even end-use parts.

- 2.6 Augmented Reality (AR) / Virtual Reality (VR): For remote expert support, training, assembly guidance, and maintenance.

- 2.7 Robotics & Automation: Collaborative robots (Cobots), Autonomous Mobile Robots (AMRs), and advanced robotic vision systems.

- 2.8 Cybersecurity: Automated industry 4.0 Course in Visakhapatnam | Securing critical industrial infrastructure from cyber threats. The IEC 62443 standard.

Module 3: Data: The Lifeblood of Industry 4.0

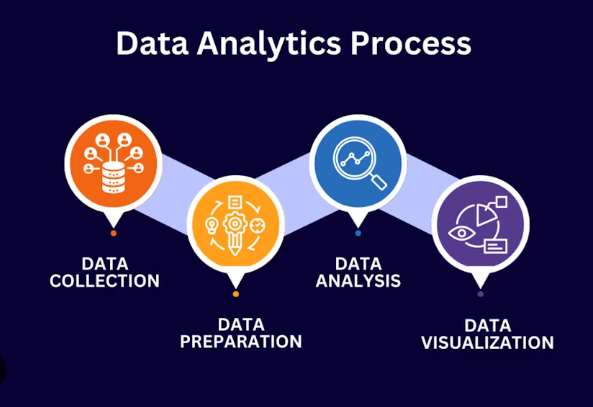

- 3.1 The Data Pipeline: Automated industry 4.0 Course in Visakhapatnam | From sensor to insight. Data acquisition, conditioning, storage, analysis, and visualization.

- 3.2 SCADA & MES Systems: Understanding the role of Supervisory Control and Data Acquisition (SCADA) and Manufacturing Execution Systems (MES) as data sources and executors.

- 3.3 The Digital Twin: Creating a virtual, dynamic replica of a physical asset, process, or system to simulate, predict, and optimize.

- 3.4 Dashboards & KPIs: Translating data into actionable insights. Using tools like Power BI, Grafana, or Tableau to monitor Overall Equipment Effectiveness (OEE), throughput, and quality in real-time.

Module 4: Connectivity & Integration

- 4.1 Industrial Networks: Automated industry 4.0 Course in Visakhapatnam | From fieldbuses (PROFIBUS) to Industrial Ethernet (PROFINET, EtherNet/IP) and Time-Sensitive Networking (TSN).

- 4.2 The IIoT Stack: Device layer, connectivity layer, cloud platform layer, and application layer.

- 4.3 System Integration: Overcoming the “islands of automation.” Integrating IT (Information Technology) with OT (Operational Technology).

- 4.4 Platform Ecosystems: Introduction to industrial IoT platforms (e.g., Siemens MindSphere, GE Predix, PTC ThingWorx, Azure IoT Hub).

Module 5: Implementing Industry 4.0 – Strategy & Roadmapping

- 5.1 Assessing Maturity: Evaluating your current state of automation and digital readiness.

- 5.2 Identifying Use Cases: Starting small with high-ROI projects (e.g., predictive maintenance on a critical asset, digital work instructions).

- 5.3 Building a Business Case: Calculating ROI, Total Cost of Ownership (TCO), and justifying investment.

- 5.4 Developing a Phased Roadmap: A practical, step-by-step approach to implementation, avoiding “boil the ocean” projects.

- 5.5 Change Management: Addressing the human factor—training, upskilling, and managing organizational change.

Module 6: Core Technologies in Action (Use Cases)

- 6.1 Predictive Maintenance: Automated industry 4.0 Course in Visakhapatnam | Using sensor data and AI to predict machine failure before it happens, reducing downtime.

- 6.2 Quality 4.0: Using machine vision and AI for automated, real-time, 100% quality inspection.

- 6.3 Asset Tracking & Optimization: Using RFID, Bluetooth LE, and UWB to track materials, tools, and WIP (Work in Progress) through the factory.

- 6.4 Energy Management: Monitoring and optimizing energy consumption across the plant.

- 6.5 Supply Chain 4.0: Creating a connected, transparent, and resilient supply chain.

Module 7: Safety, Ethics, and The Future of Work

- 7.1 Human-Robot Collaboration (HRC): Automated industry 4.0 Course in Visakhapatnam | Safety standards (ISO/TS 15066) for deploying cobots.

- 7.2 Workforce Transformation: The changing nature of jobs. Upskilling from manual tasks to analytical and problem-solving roles.

- 7.3 Ethical Considerations: Data privacy, algorithmic bias in AI, and the societal impact of automation.

- 7.4 Sustainability: How I4.0 technologies contribute to greener manufacturing through optimized resource usage.

Module 8: Capstone Project – Design a Smart Factory Cell

- Automated industry 4.0 Course in Visakhapatnam | Students will design a conceptual Smart Factory cell for a simple product (e.g., custom USB drive assembly).

- Deliverables include:

- A technology roadmap proposing a phased implementation.

- A architecture diagram showing the flow of data from sensors to the cloud and back.

- A selection of specific technologies (e.g., type of robot, sensors, communication protocol, analytics platform).

- Identification of key performance indicators (KPIs) to measure success.

- A risk assessment covering cybersecurity and implementation challenges.

- Automated industry 4.0 Course in Visakhapatnam | This project tests the ability to synthesize all course concepts into a coherent plan.

Recommended Tools & Technologies (for Labs)

- Simulation: Factory I/O, Siemens NX Plant Simulation, or AnyLogic.

- Data Visualization: Microsoft Power BI, Grafana

- IIoT Platform: Node-RED (for concept prototyping), Microsoft Azure IoT Suite

- Cobot Simulators: Universal Robots URSim, FANUC ROBOGUIDE

Learning Outcomes

Upon completion, students will be able to:

- Automated industry 4.0 Course in Visakhapatnam | Articulate the core concepts, drivers, and benefits of Industry 4.0.

- Identify and describe the function of key enabling technologies (IIoT, AI, Digital Twin, Cobots, Additive Manufacturing).

- Understand the flow of data in a smart factory and its role in decision-making.

- Evaluate the maturity of a manufacturing operation and identify high-value Industry 4.0 use cases.

- Develop a strategic roadmap for a phased implementation of Industry 4.0 technologies.

- Understand the critical importance of cybersecurity and change management in digital transformation.

- Design a conceptual smart factory solution that integrates multiple I4.0 technologies.

Automated industry 4.0 Course in Visakhapatnam | This course is strategic and technological, blending business acumen with engineering knowledge. It is designed not to create experts in each technology, but to create “translators” and architects who can bridge the gap between the shop floor and the executive boardroom, driving successful digital transformation.