The Additive Manufacturing (3D Printing) provides comprehensive training on modern 3D printing technologies, materials, and applications. Participants will gain hands-on experience in designing, prototyping, and producing components using additive manufacturing methods. This course is ideal for engineers, designers, and professionals looking to enhance their skills in advanced manufacturing techniques.

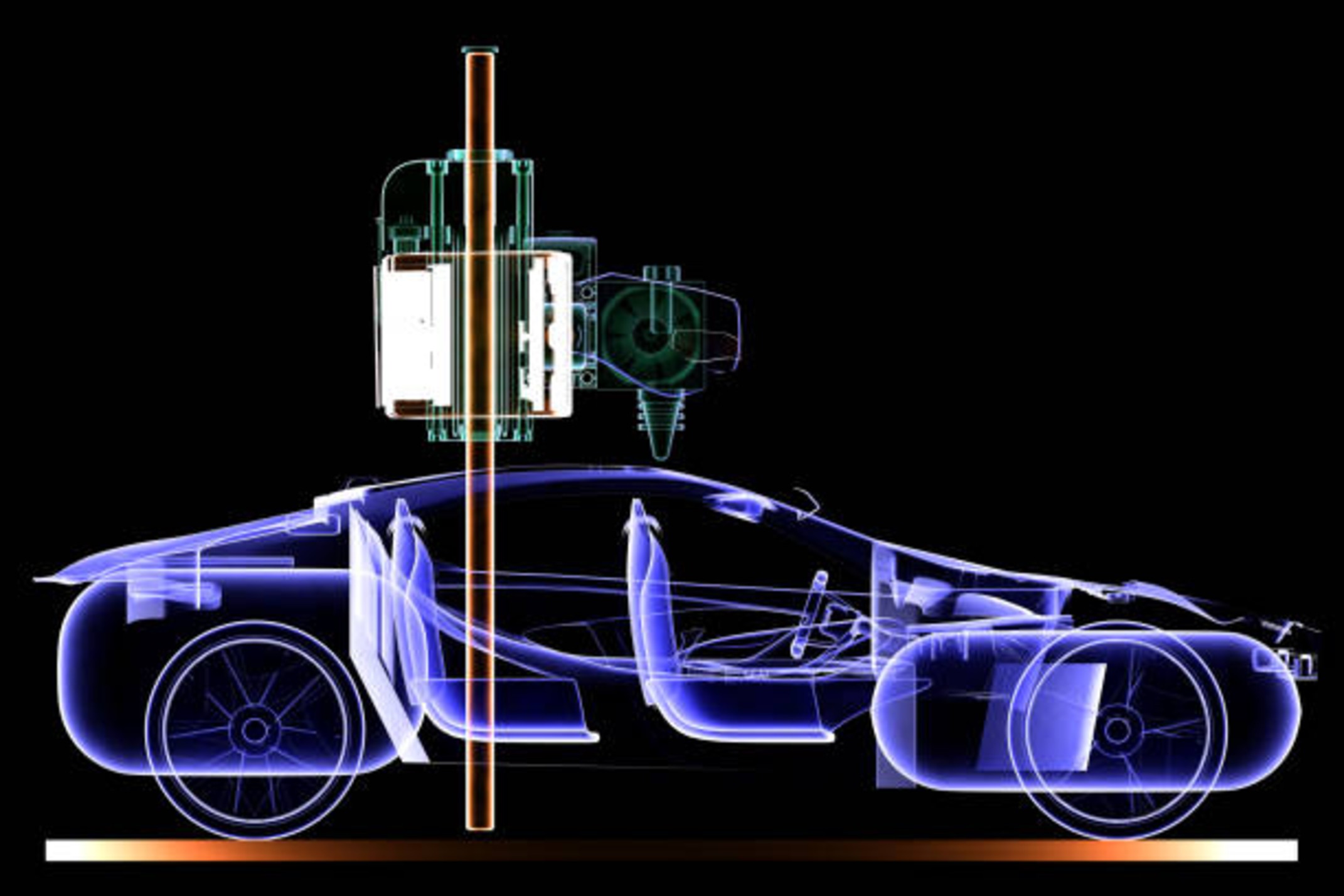

Introduction to Additive Manufacturing Overview of additive vs. traditional manufacturing History and evolution of 3D printing Key industry applications Advantages and limitations of additive manufacturing.

3D Printing Technologies Fused Deposition Modeling (FDM) Stereolithography (SLA) Selective Laser Sintering (SLS) Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM) Emerging technologies: Binder Jetting, Electron Beam Melting (EBM), Multi-material printing.

Materials in Additive Manufacturing Polymers: PLA, ABS, Nylon, PETG Metals: Stainless steel, Titanium, Aluminum Composites and ceramics Material selection based on application requirements.

CAD for 3D Printing Introduction to CAD software (SolidWorks, AutoCAD, Fusion 360) 3D modeling techniques for additive manufacturing Design for additive manufacturing (DfAM) principles Topology optimization and lightweight structures.

Slicing and Printing Preparation Understanding slicing software: Cura, PrusaSlicer, Simplify3D Layer height, infill, support structures Print orientation and optimization techniques File formats and printer compatibility.

3D Printing Process & Machine Operation Setting up and calibrating 3D printers Understanding printing parameters and their effects Troubleshooting common printing issues Hands-on practice with different types of 3D printers.

Post-Processing Techniques Cleaning, sanding, and polishing Heat treatment and curing processes Surface finishing and coating methods nInspection and testing of printed parts.

Additive Manufacturing in Industry Applications in aerospace, automotive, healthcare, and consumer products Case studies of real-world industrial use Integration of additive manufacturing in production workflows.

Quality Control & Inspection Dimensional accuracy and tolerance verification Mechanical property testing Non-destructive testing (NDT) techniques Standards and certifications in additive manufacturing.

Future Trends & Emerging Technologies Multi-material and hybrid 3D printing Bioprinting and medical applications AI and simulation in additive manufacturing Sustainability, recycling, and the future of 3D printing.

Mobile: 9100348679

Email: coursedivine@gmail.com

You cannot copy content of this page