Course Description:

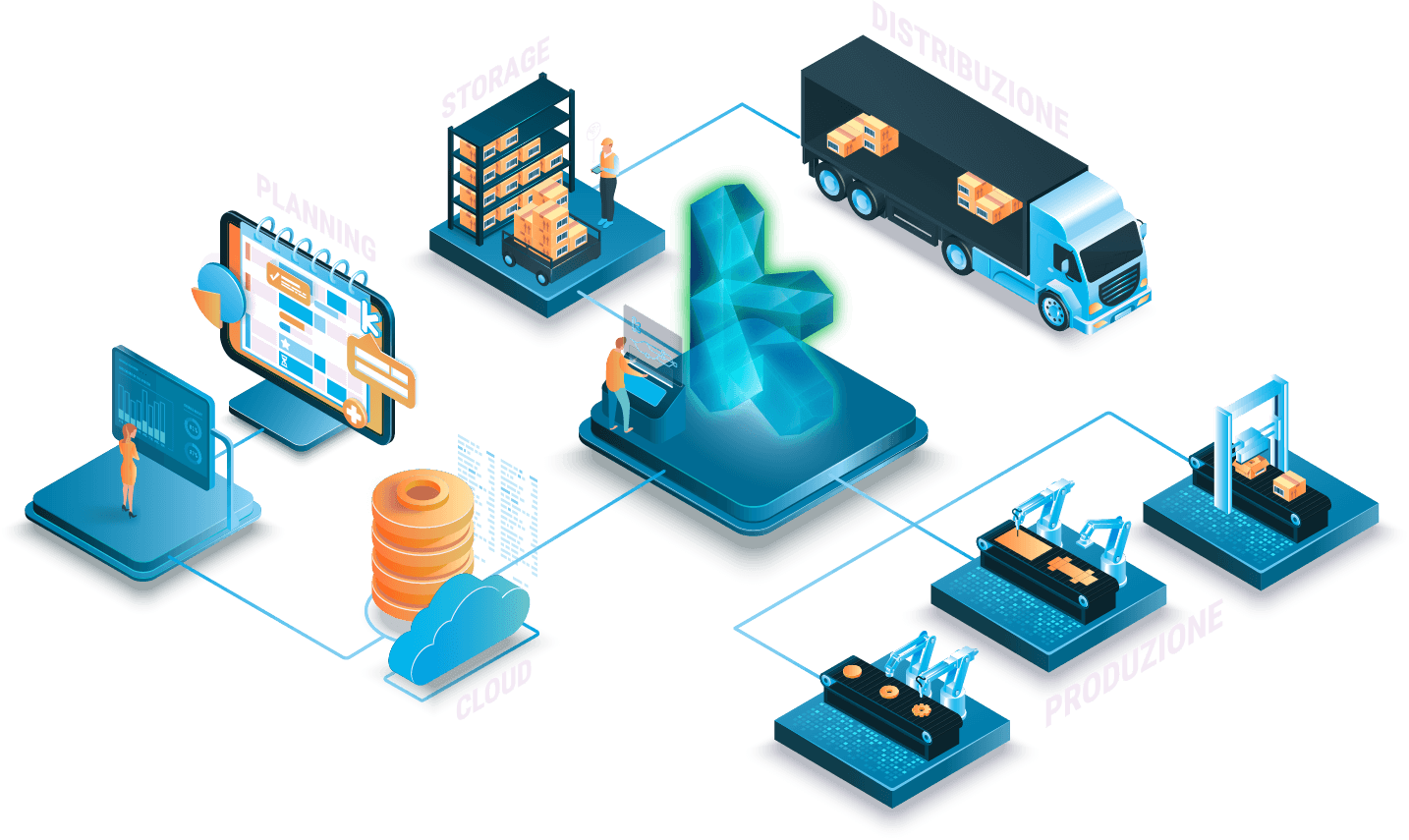

The Advanced Production Planning & Detailed Scheduling (Industry 4.0) is a cutting-edge course designed to equip learners with modern planning and scheduling techniques used in smart manufacturing environments. The program covers advanced production planning concepts, detailed shop-floor scheduling, demand forecasting, capacity planning, and real-time decision-making using Industry 4.0 technologies. Learners gain hands-on exposure to digital tools, data-driven optimization, IoT-enabled production systems, and simulation-based scheduling to improve efficiency, reduce lead times, and enhance resource utilization. This course is ideal for professionals and students aiming to build expertise in intelligent manufacturing, smart factories, and advanced operations management aligned with global industry standards.

Key Features of Course Divine:

- Collaboration with E‑Cell IIT Tirupati

- 1:1 Online Mentorship Platform

- Credit-Based Certification

- Live Classes Led by Industry Experts

- Live, Real-World Projects

- 100% Placement Support

- Potential Interview Training

- Resume-Building Activities

Career Opportunities After Completing Advanced Production Planning & Detailed Scheduling (Industry 4.0):

- Production Planning Engineer

- Production Scheduler

- Manufacturing Planning Analyst

- Operations Planning Specialist

- Supply Chain Planning Analyst

- Smart Manufacturing Engineer

- Industrial Engineer (Planning & Optimization)

- Factory Planning Consultant

- Digital Manufacturing Specialist

- Capacity Planning Engineer

- Demand Planning Analyst

- Shop Floor Control Engineer

- Industry 4.0 Implementation Engineer

- Manufacturing Operations Manager

- Process Optimization Engineer

Essential Skills You Will Develop Advanced Production Planning & Detailed Scheduling (Industry 4.0) Certified Course:

- Advanced production planning techniques

- Detailed scheduling and sequencing methods

- Capacity planning and resource optimization

- Demand forecasting and planning analysis

- Industry 4.0 concepts and smart manufacturing

- Data-driven decision making

- Real-time production monitoring

- Manufacturing process optimization

- Supply chain coordination skills

- Digital tools for planning and scheduling

- Simulation and scenario analysis

- Lean and agile manufacturing principles

- Problem-solving in complex production systems

- Cross-functional operations management

- Continuous improvement and performance analysis

Tools Covered:

- SAP PP (Production Planning)

- SAP APO (Advanced Planning & Optimization)

- SAP IBP (Integrated Business Planning)

- MES (Manufacturing Execution Systems)

- ERP-based planning modules

- Advanced Excel for planning & scheduling

- APS (Advanced Planning & Scheduling) software

- Simulation tools (e.g., Arena, FlexSim)

- IoT-based production monitoring tools

- Data analytics tools for demand forecasting

Syllabus:

Module 1:

Introduction to Advanced Production Planning Overview of production planning Role in Industry 4.0 Key challenges and objectives.

Module 2:

Demand Forecasting & Planning Forecasting techniques (qualitative & quantitative) Sales & operations planning (S&OP) Demand-driven planning.

Module 3:

Capacity Planning & Resource Management Work center and resource capacity analysis Load leveling and capacity balancing Bottleneck identification.

Module 4:

Detailed Scheduling & Sequencing Shop floor scheduling techniques Order prioritization & sequencing rules Finite vs infinite scheduling.

Module 5:

Advanced Planning Tools & Software SAP PP, SAP APO, SAP IBP APS (Advanced Planning & Scheduling) software MES integration with planning.

Module 6:

Industry 4.0 in Manufacturing Smart factories and digital twin concepts IoT-enabled production monitoring Real-time decision making.

Module 7:

Simulation & Scenario Analysis Production simulation techniques Scenario planning & optimization What-if analysis for planning.

Module 8:

Lean & Agile Manufacturing PracticesLean principles in planning & scheduling Just-in-time (JIT) production Agile production strategies.

Module 9:

Data Analytics for Planning & Scheduling Data-driven decision making KPIs and performance monitoring Predictive analytics for production.

Module 10:

Capstone Project / Industry Case Studies Hands-on industry projects Real-world problem-solving Integration of all modules for end-to-end planning.

Industry Projects:

- Smart Factory Production Planning

- Shop Floor Scheduling Optimization

- Demand Forecasting & Inventory Management

- Capacity Planning Simulation

- Industry 4.0 Implementation Case Study

- Advanced Planning Software

- Lean & Agile Production Improvement

- Predictive Analytics in Manufacturing

- Scenario Planning & What-if Analysis

- End-to-End Capstone

Who is this program for?

- Manufacturing engineers aiming to enhance production planning skills

- Production planners and schedulers seeking advanced Industry 4.0 techniques

- Supply chain and operations professionals

- Industrial engineers looking to specialize in smart manufacturing

- ERP/SAP professionals wanting to strengthen planning and scheduling expertise

- Managers responsible for factory operations and resource optimization

- Professionals in lean, agile, or digital transformation roles

- Engineering graduates planning a career in advanced manufacturing

- Consultants working in manufacturing efficiency and process optimization

- Anyone interested in Industry 4.0 technologies and smart factory implementation

How To Apply:

Mobile: 9100348679

Email: coursedivine@gmail.com